Understanding Bulk Material Handling: A Guide for the Electronics and 3D Printing Industries

Bulk material handling is a critical aspect in various industries, particularly in sectors like electronics and 3D printing, where efficiency and accuracy in handling materials can significantly affect production outcomes. In this article, we'll delve deep into what bulk material handling entails, explore its importance, and highlight innovative practices and technologies that can enhance productivity for businesses like Polygon Machinery.

What is Bulk Material Handling?

Bulk material handling refers to the process of handling large volumes of bulk materials in an efficient and effective manner. This process involves various activities including transporting, storing, and controlling the flow of materials in a systematic way. In industries like electronics, where precision is paramount, handling materials properly can lead to significant advantages, including reduced waste, improved quality of products, and increased overall operational efficiency.

The Importance of Bulk Material Handling

Understanding the significance of bulk material handling is essential for any business in the manufacturing and industrial sectors. Below are some key reasons why efficient bulk material handling is crucial:

- Cost Efficiency: Optimized handling reduces labor costs and improves the utilization of materials, leading to lower overall operational expenses.

- Increased Productivity: Streamlined processes can speed up material flow, allowing for faster production times and meeting customer demand promptly.

- Improved Safety: Proper handling protocols and equipment minimize hazards, ensuring a safer working environment for employees.

- Higher Quality: Consistent handling practices help maintain the integrity of materials, crucial in sectors like electronics where quality control is vital.

- Sustainability: Efficient material handling can reduce waste and energy consumption, contributing to more sustainable business practices.

Techniques in Bulk Material Handling

Adopting the right techniques in bulk material handling is essential for optimizing operations. Some of these techniques include:

1. Automated Material Handling Systems

Implementing automated systems such as conveyors, robotic arms, and automated guided vehicles (AGVs) can greatly enhance the efficiency of bulk material handling. These systems are designed to minimize human intervention, thereby reducing errors and increasing speed. Companies like Polygon Machinery can benefit from integrating automation into their handling processes.

2. Proper Storage Solutions

Effective storage solutions are crucial in bulk material handling. Utilizing systems such as racking, shelving, or silos ensures that materials are stored correctly, making retrieval easier and faster, which is vital in workflows involving electronics and 3D printing.

3. Inventory Management

Implementing robust inventory management techniques allows companies to keep track of material usage effectively, minimizing shortages and excesses. Advanced software solutions can help manage inventory levels in real time, promoting a more responsive supply chain.

Technological Innovations in Bulk Material Handling

As technology evolves, so do the methods and equipment for bulk material handling. Here are some innovative technologies making an impact:

1. Internet of Things (IoT)

The integration of IoT in material handling allows for real-time monitoring of equipment and materials. Companies can gather data on operational performance, identify bottlenecks, and make informed decisions. This approach enhances the visibility of material movement across various processes.

2. Artificial Intelligence (AI)

AI systems can optimize logistics and supply chain decisions, predicting future material needs based on historical data. This predictive capability can help businesses prepare better for demand fluctuations, ensuring smooth operations in the electronics and 3D printing sectors.

3. Augmented Reality (AR)

AR technology enables workers to visualize material handling processes in a more interactive way. Training programs using AR can enhance the learning experience, allowing operators to understand complex systems better before engaging with actual equipment.

Best Practices for Efficient Bulk Material Handling

To maximize the benefits of bulk material handling, adopting best practices is essential. Here are some recommendations:

1. Regular Training and Safety Protocols

Providing regular training for employees on handling equipment and safety protocols ensures that all personnel are equipped to handle materials efficiently and safely. Regular refreshers and updates on best practices can further mitigate risks.

2. Maintenance of Equipment

Maintenance of handling equipment is crucial. Implementing a routine maintenance schedule ensures that machinery is in optimal working condition, reducing downtime and unexpected breakdowns.

3. Continuous Improvement

Encouraging a culture of continuous improvement allows companies to stay ahead of the curve. Regularly reviewing handling processes and seeking feedback from employees can reveal areas for enhancement and innovation.

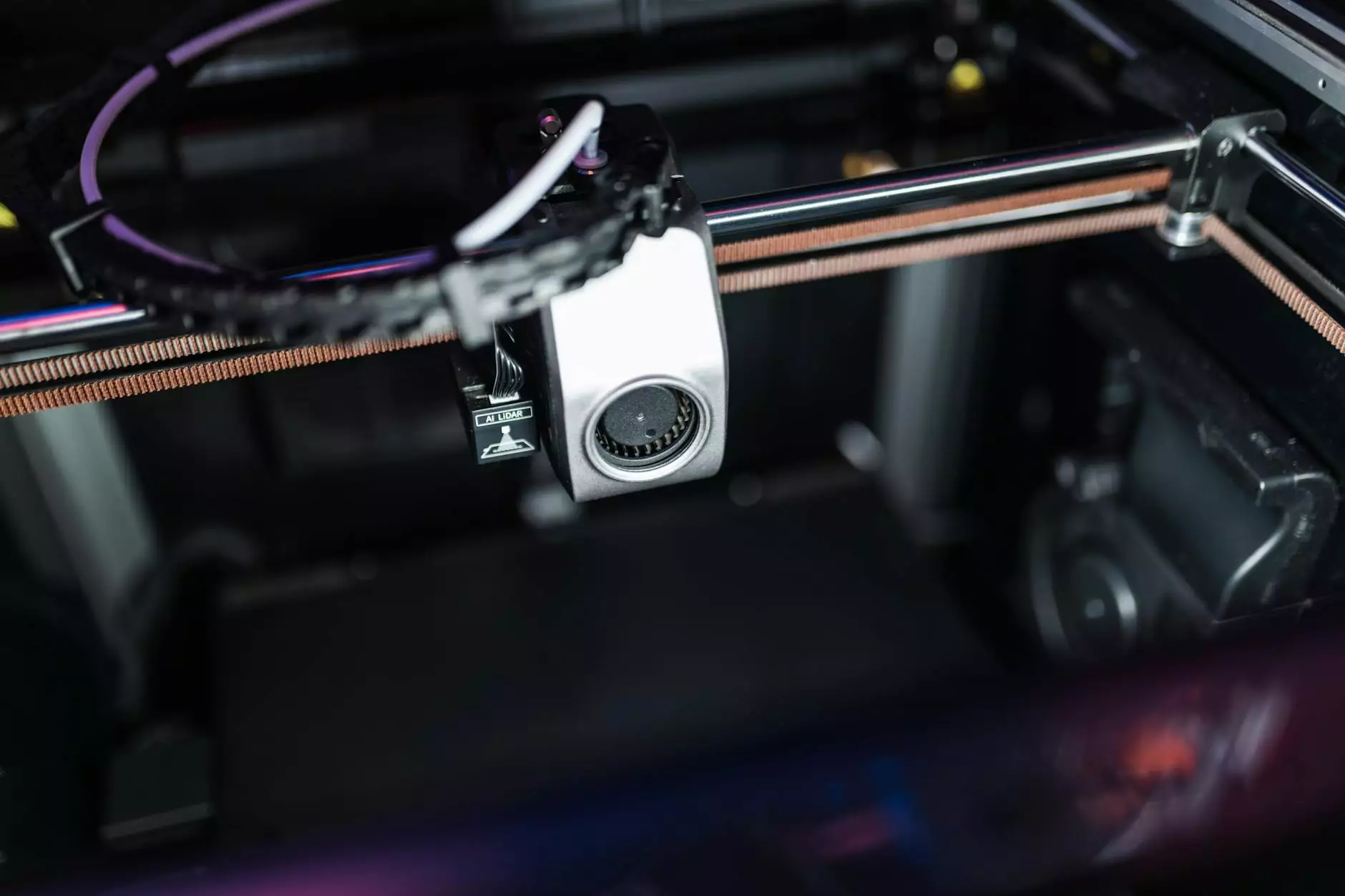

The Role of Bulk Material Handling in 3D Printing

In the world of 3D printing, bulk material handling plays a significant role in ensuring the availability and quality of raw materials. Here’s how:

- Material Quality: The quality of materials used in 3D printing directly impacts the final product. Proper handling methods help preserve material properties during storage and transportation.

- Operational Flexibility: Efficient bulk material handling allows manufacturers to switch between different materials as needed, enhancing production flexibility and responsiveness to market demands.

- Reducing Material Waste: By optimizing the handling processes, manufacturers can minimize waste of expensive materials often used in 3D printing, leading to cost savings.

Future Trends in Bulk Material Handling

As industries continue to evolve, the landscape of bulk material handling is set to change significantly. Upcoming trends include:

1. Increased Automation

The future will see a rise in automation across all levels of material handling. As costs decrease and technology improves, more companies will adopt robotic systems to streamline the handling of bulk materials.

2. Smart Warehousing

With advancements in AI and IoT, smart warehousing will enable better inventory predictions, greater efficiency, and more adapted environments for handling bulk materials. This transformation will align with the growing demands of e-commerce and rapid production cycles.

3. Sustainable Practices

More businesses will focus on sustainable practices within their material handling processes. Trends toward reducing carbon footprints and adopting eco-friendly materials will become more prominent in bulk material handling strategies.

Case Studies: Successful Implementations of Bulk Material Handling Strategies

Understanding how other businesses have effectively implemented bulk material handling strategies can provide valuable insights. Consider the following case studies:

Case Study 1: Polygon Machinery

Polygon Machinery has leveraged automation in their bulk material handling processes to significantly reduce operational costs while enhancing efficiency. Implementing an automated inventory management system helped them reduce material waste and improve delivery times, which are critical factors in the electronics sector.

Case Study 2: 3D Printing Innovator

A leading 3D printing company increased their production capacity by 30% through the implementation of smart warehouse technologies. By utilizing IoT for real-time inventory tracking and automating bulk material transfers, they achieved not only faster production but also a notable reduction in material losses.

Conclusion

In conclusion, bulk material handling plays a pivotal role in the efficiency and success of industries like electronics and 3D printing. By adopting innovative technologies, implementing best practices, and continuously seeking improvement, businesses can significantly enhance their operational capabilities. As we look to the future, staying abreast of emerging trends and technologies will be essential for sustaining competitive advantages and achieving business goals. Companies such as Polygon Machinery are at the forefront of these developments, leading the way in optimizing bulk material handling strategies.